Traditionally, shipping any type of product is associated with a shipping cost; in the business, we call this freight. Freight is a calculated cost by the weight of the shipment but may also include costs for distance between the distribution center and the destination.

Modern and more advanced logistics has created the need for more efficient and pragmatic distribution methods. After years of shipping lightweight goods in oversized, and altogether poorly sized packaging, experts in the supply chain industry realized it was time for a change, and so came the adoption of dimensional – or DIM – weight policy.

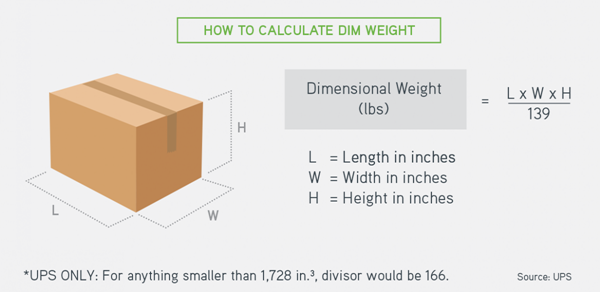

DIM weight refers to the cost associated with the dimensions, or size, of a package. It is calculated by taking the volume of the package (LengthxWidthxHeight) and dividing it by the DIM factor (166 or 139, depending if US or International). The number calculation refers to the “pounds” in dimensional weight.

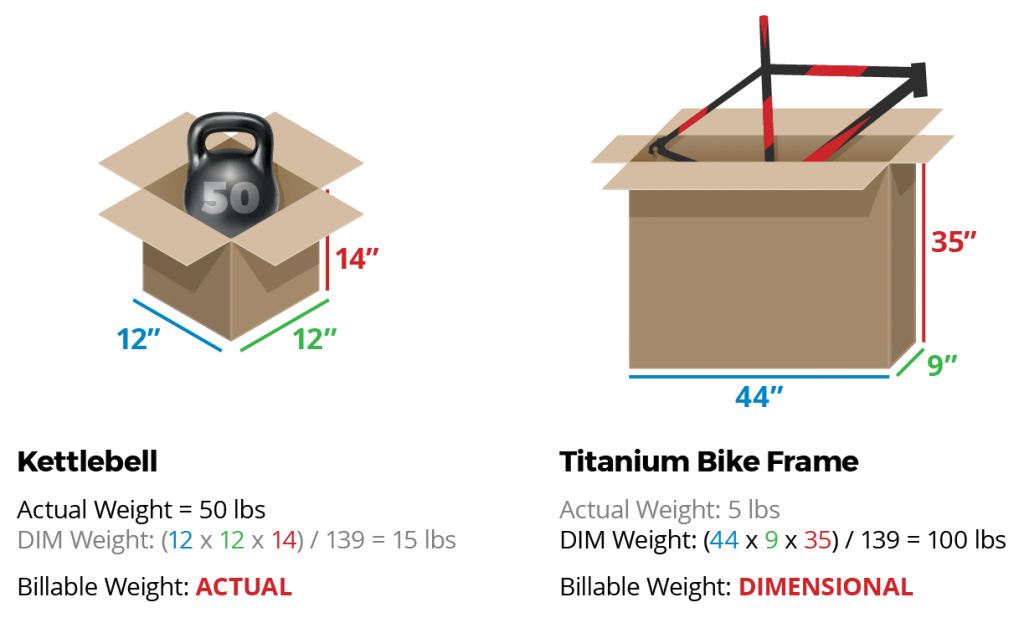

In the shipping process, both freight and DIM weight are calculated, and the larger of the two weights is used for cost. In the example below, see how the cost to ship a 50lb Kettlebell in a 12x12x14 box is taken by the actual weight of the box, since that is more than the DIM weight, and the lighter, titanium bike frame, although only 5 lbs., measures in at a DIM weight of 100 lbs. and will be billed on that number.

The purpose of DIM weights is to discourage the shipping of items in unnecessarily large packaging, and its adoption by common carriers has led to decreased waste from unnecessary amounts of packaging and increased space on pallets and trailers space for more optimized distribution. DIM weight relies on using the right size or specific packaging materials to fit product needs, and not a “one size fits all” approach. Using DIM weight as a new guideline, companies have cut costs across the board on their shipping businesses.

Packaging experts can provide solutions for right-sized packaging, thus decreasing DIM weights of shipped goods. There are hundreds of ways to reduce DIM weight for virtually any type of distribution, including using appropriately sized corrugated boxes, adding or changing void fill or cushioning products, and having a better understanding of necessary packaging needed for distributed product.

Calculate DIM weight using this DIM Weight Calculator from Fedex.